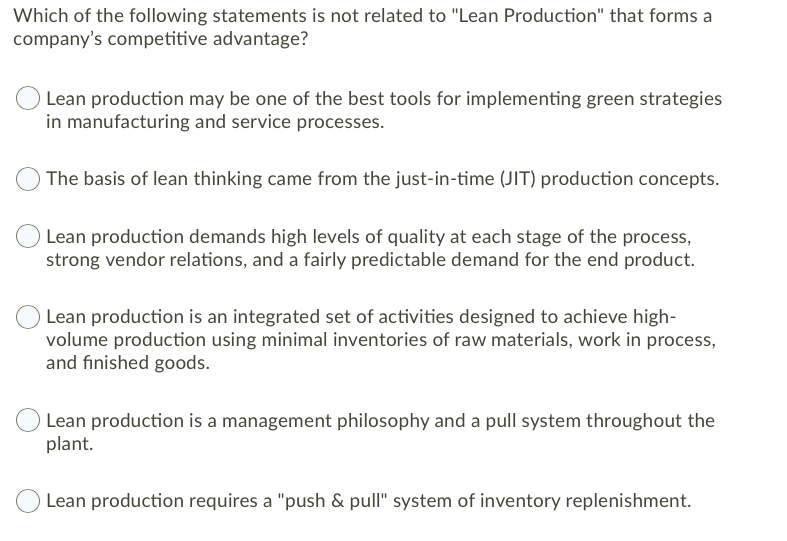

Lean Production Requires A Push And Pull System Of Inventory Replenishment

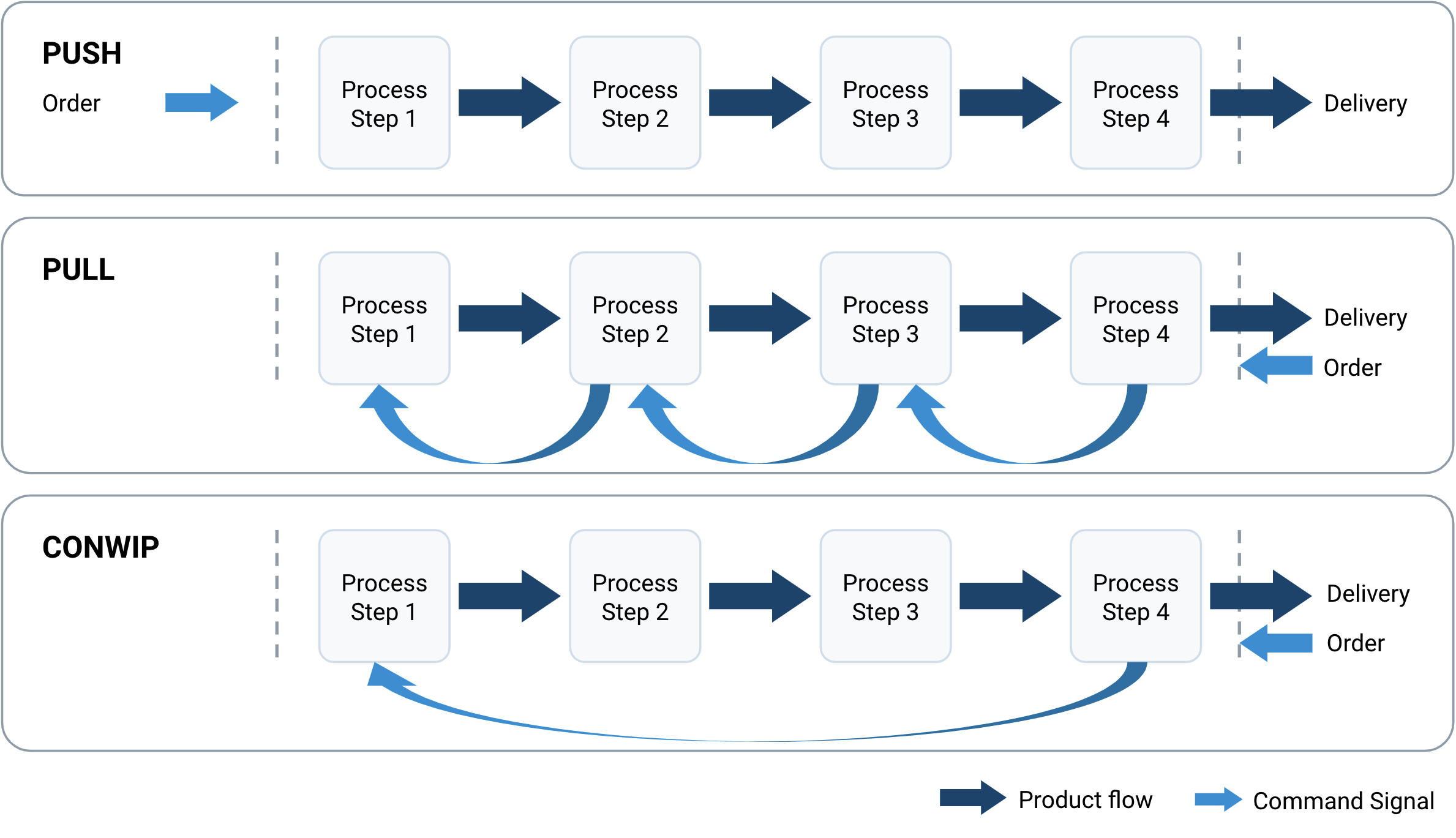

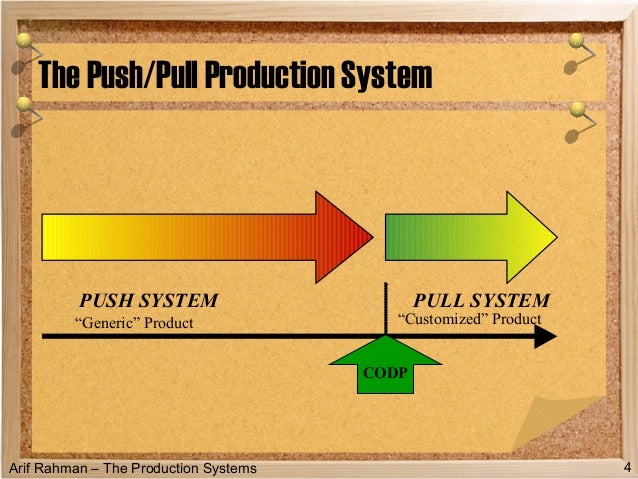

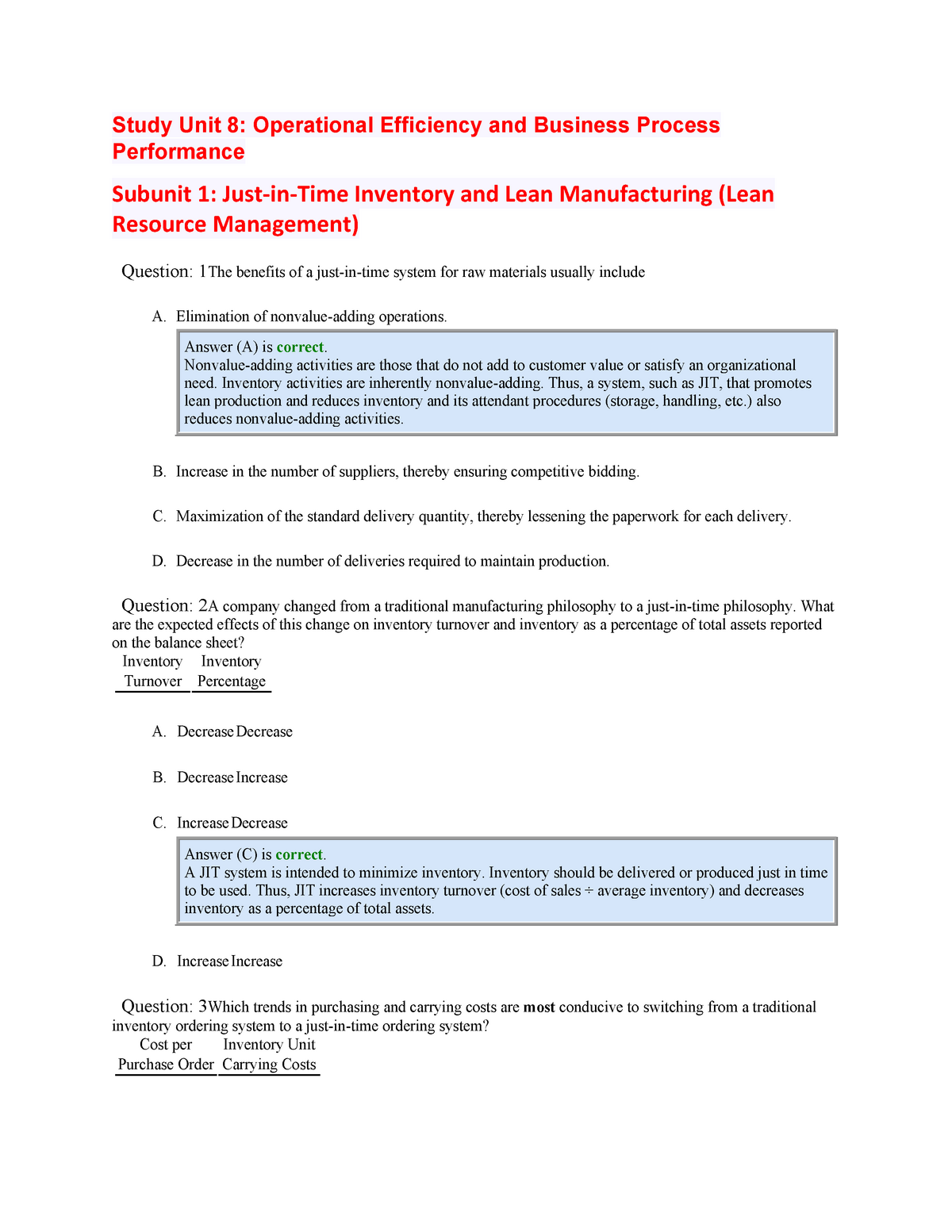

Lean production requires a push and pull system of inventory replenishment. Pull methods force processes to improve so they increase flexibility and reduce inventory. Push-pull systems often use the economic order quantity EOQ formula to determine how. With this system you place smaller orders more frequently than you would under the push system.

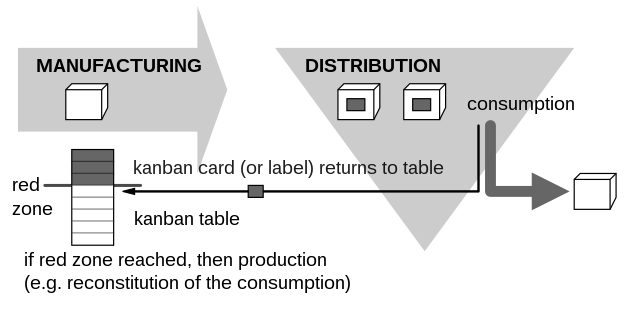

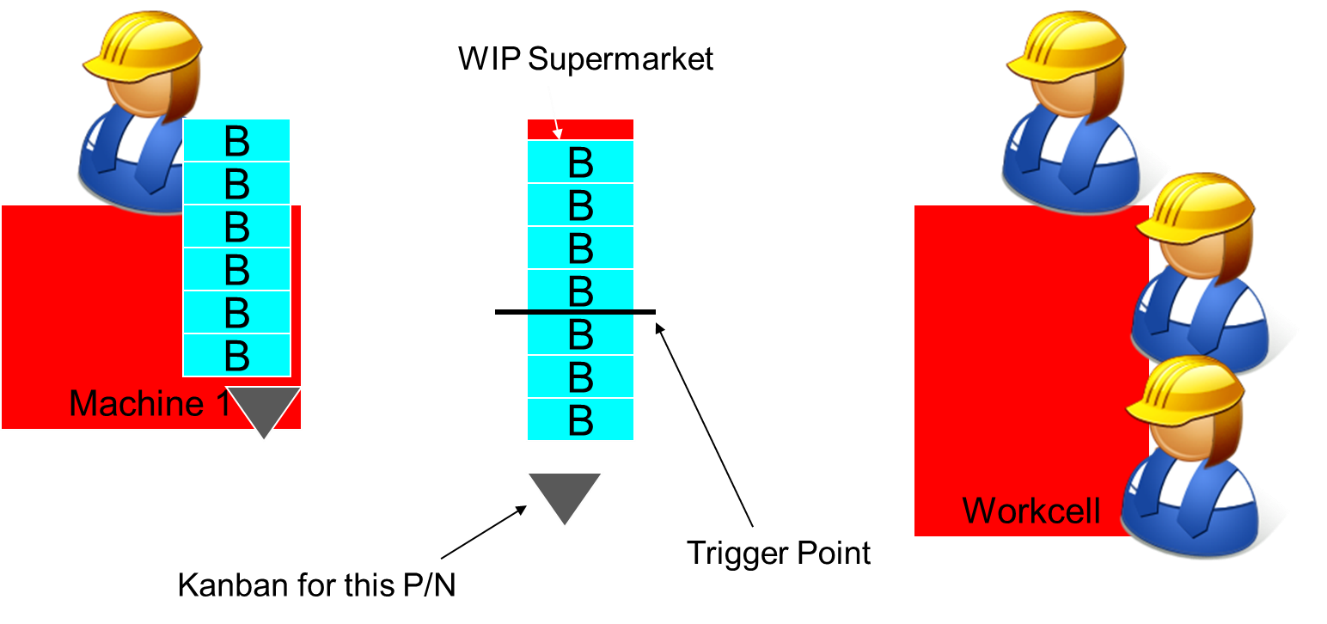

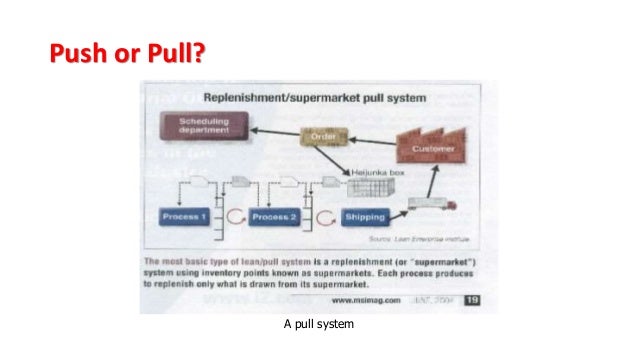

Lean production requires a push and pull system of inventory replenishment. WS SS RS Trigger point for reorder is. Applying a pull system allows you to start new work only when there is customer demand for it.

This allows you to reduce overhead and optimize storage costs. There are essentially two different types of pull systems. Sequential pull and replenishment or supermarket pull.

Lean production requires a push and pull system of inventory replenishment. Pull Systems A pull system is one that is set up to respond directly to internal or external customer demand. While convenient the push system is ultimately only as effective as the forecasts on which it is based.

Changes to customer demand can be made more quickly. In the pull system of inventory management you monitor current sales and place orders accordingly. Replenishment Pull Operation Maximum Inventory in the System is.

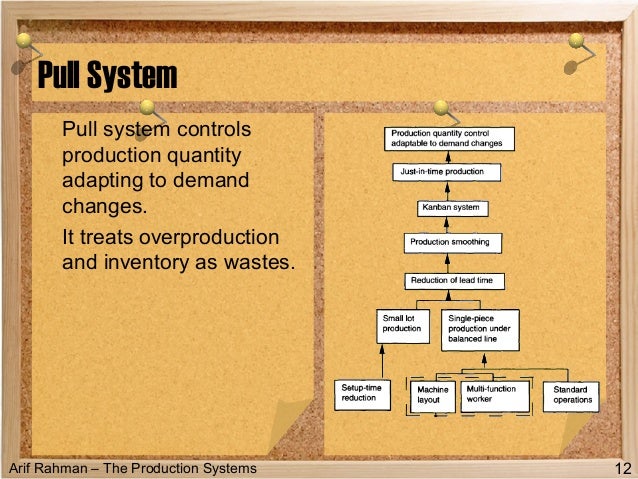

Only immediate customer requirements are drawn from the protective inventories upstream. Because this strategy usually requires a general comprehensive approach to stock keeping units SKUs and decision points it often results in broad inventory replenishment orders that are not always sensitive to differences in demand. A pull system is a Lean technique for reducing the waste of any production process.

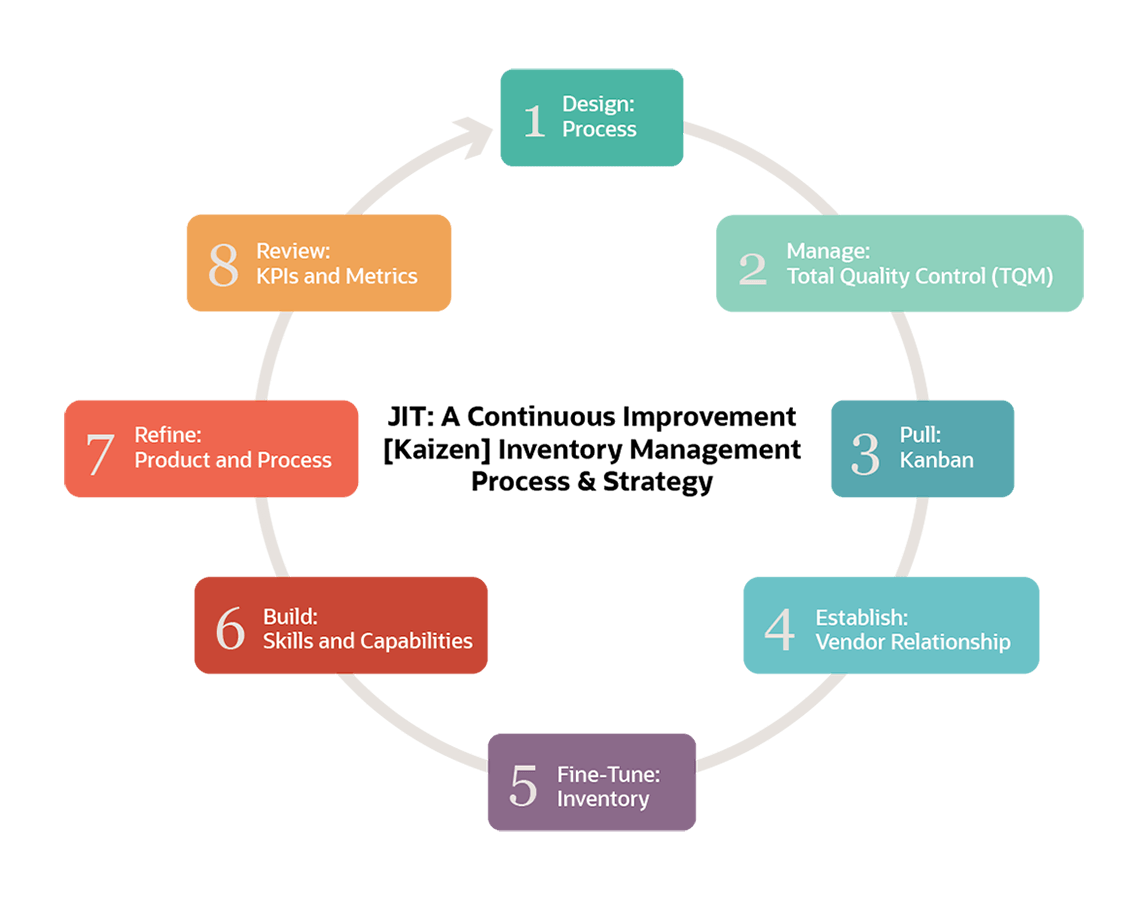

With a pull system you want to have just enough inventory on hand to satisfy demand with perhaps a little extra for unexpected surges in a products popularity. Pull production strives to eliminate overproduction and is one of the three major components of a complete just-in-time production system.

Applying a pull system allows you to start new work only when there is customer demand for it.

F Lean production replaced JIT in the 1990s because JIT did not address the problem of reducing waste. Lean production requires a push and pull system of inventory replenishment. Cycle time 5 days Lead time 10 days Demand 2 day SS 2 pieces. There are essentially two different types of pull systems. Departments within the firm often are at odds with each other because reward systems are often not synchronized with the basic goal of the firm. You should only be starting production once a customer has requested the item. Push-pull is also known as lean inventory strategy. With this system you place smaller orders more frequently than you would under the push system. Pull Systems A pull system is one that is set up to respond directly to internal or external customer demand.

Its key feature is to have an upper limit on inventory that is not to be exceeded. Pull production strives to eliminate overproduction and is one of the three major components of a complete just-in-time production system. Why Is Pull Better Than Push. F Lean production replaced JIT in the 1990s because JIT did not address the problem of reducing waste. Lean production requires a push and pull system of inventory replenishment. Pull systems use demand data to drive both replenishment and production. Pull is preferred in a Lean process It is better for most organizations to use pull methods since the customer not the company determines when to pull value in Lean.

.jpeg)

Post a Comment for "Lean Production Requires A Push And Pull System Of Inventory Replenishment"